Hand Tools

Is a half helmet safe on a motorcycle?

There is a lot of debate about whether or not a half helmet is safe on a motorcycle. Some people swear by them, while others think they are just asking for an accident.

Pick seat covers for Honda CRV

When it comes to making a decision about what seat covers for Honda CRV to buy for, there are three main factors you need to consider: protection, comfort, and style.

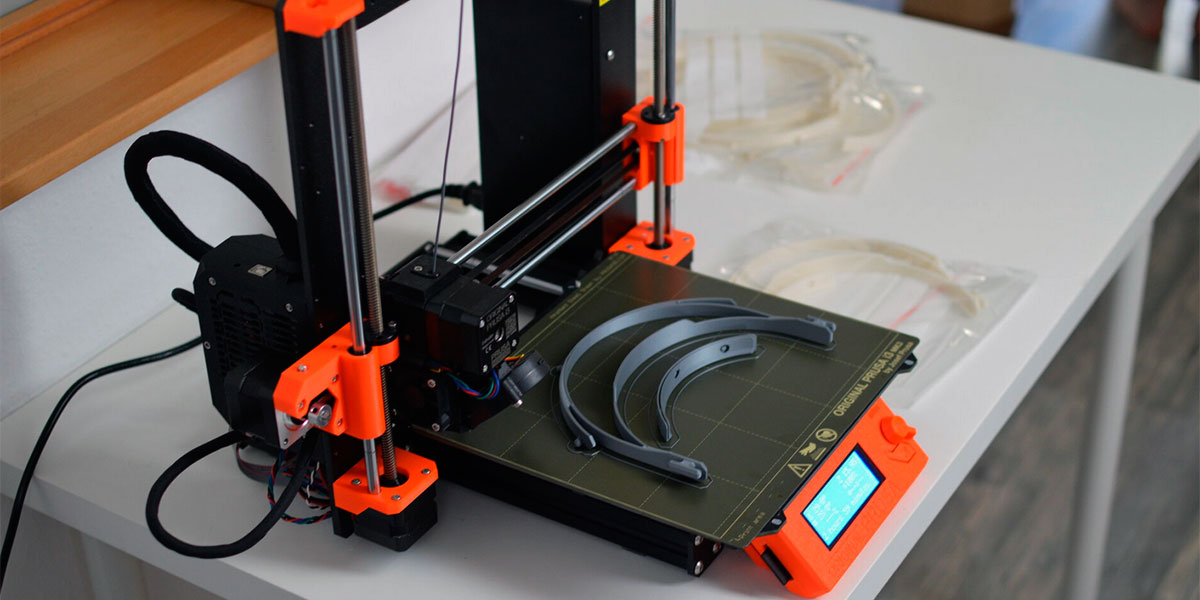

3D Printed Spare Parts Quality Guideline

In the modern age of 3D printing, new opportunities are arising for engineers and designers.

How To Use A Heat Gun: DIY Tips and Tricks

Heat guns are an excellent tool for DIYers and handypersons. They can be used to paint, drywall, strip paint, thaw pipes, or just about anything else you need heat for.

Tips for Maintaining Your 3D Printer

A 3D printer is a very powerful tool that can be used for many purposes. One of the most common reasons people purchase them is that they will need them to print out parts and items for their other projects

Different Types of Jigsaw Blade

There are a number of factors at play when it comes to choosing the best jigsaw blades, such as the type of material you are cutting, the type of cuts, and the type of blade you select.

Methods of Paint Application for Your Next DIY Project

I am here to help you with your next DIY project. I will be going over the different methods of paint application for your next painting project.

Factors to Consider When Selecting Tool Grade Steel

This article will take you through the most common tool steel grades, explain their properties, and give some examples of what they are used for.